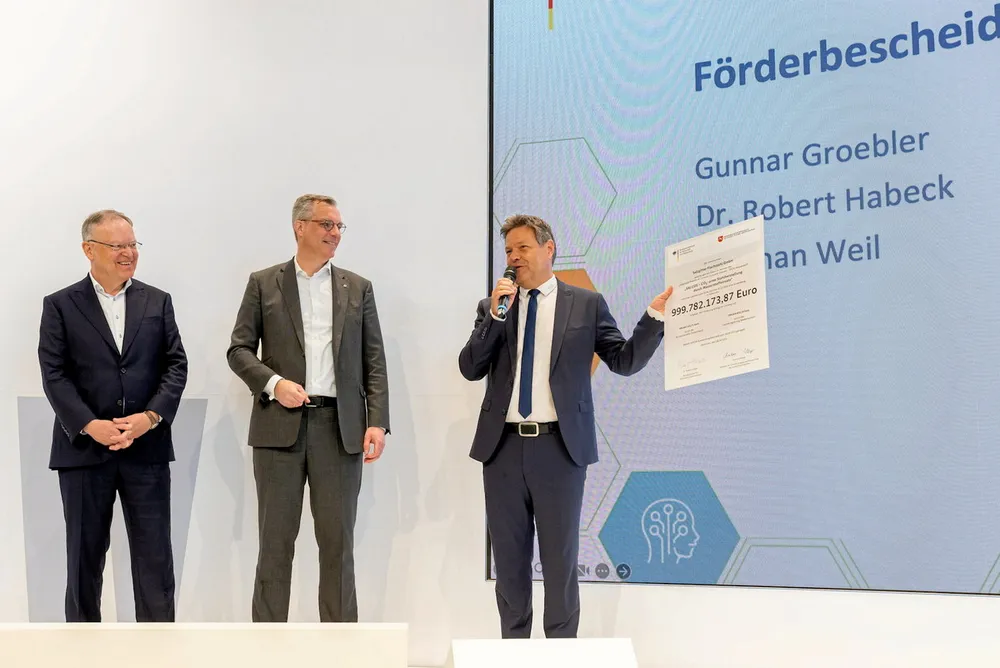

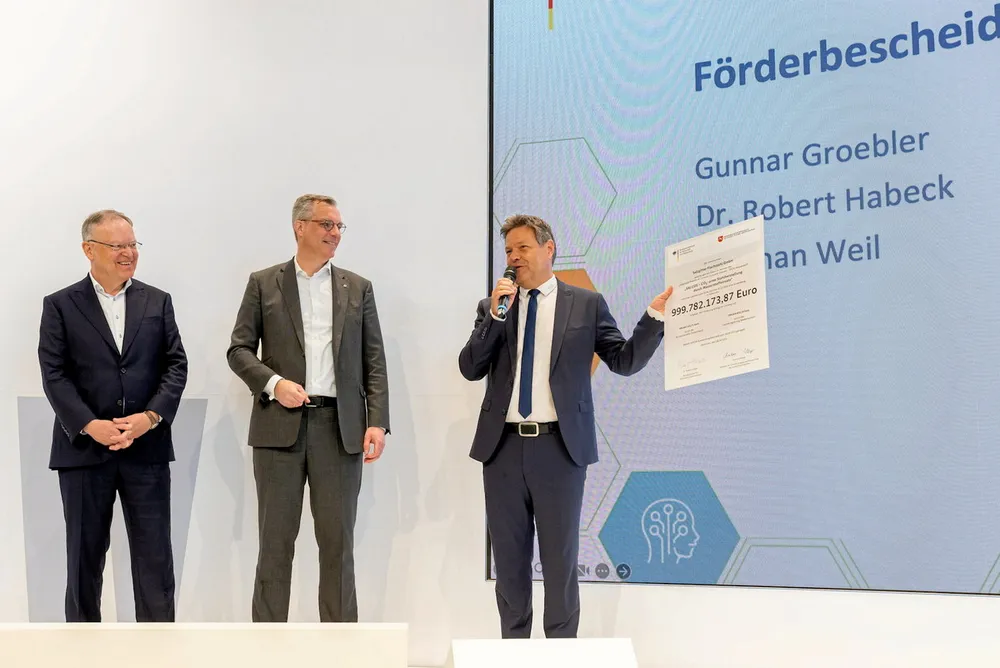

Salzgitter to start converting to green hydrogen-based steel production by 2026 as it bags €1bn in public subsidy

Renewable H2 at the heart of German steel giant’s plans to replace polluting ironmaking furnaces with direct reduced iron (DRI) plants

Renewable H2 at the heart of German steel giant’s plans to replace polluting ironmaking furnaces with direct reduced iron (DRI) plants