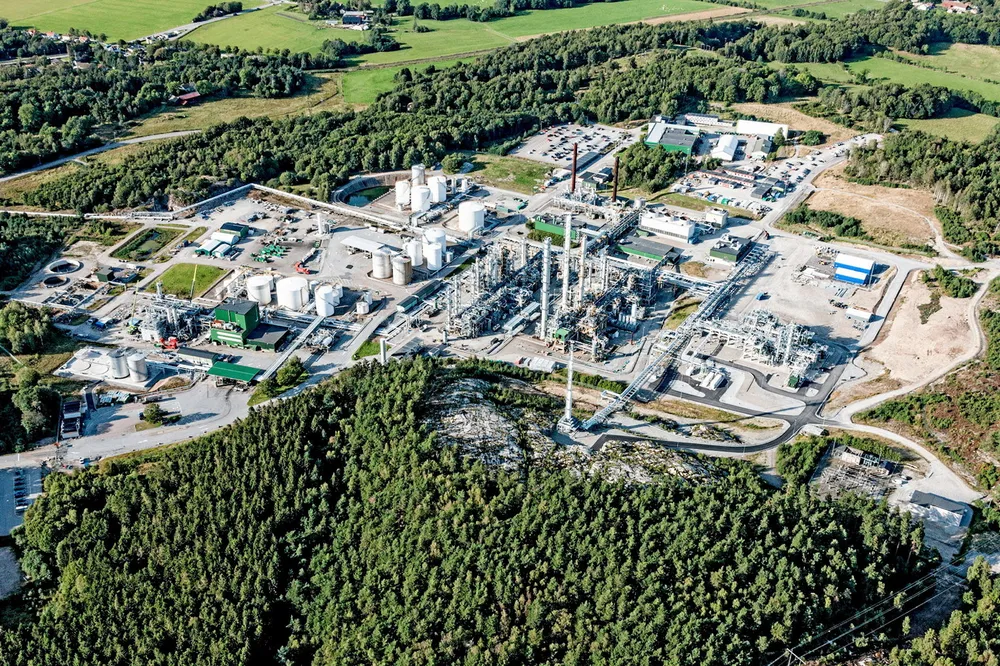

'Transforming the chemicals industry' | Large-scale green methanol plant in Sweden receives €97m of EU funding

Project Air will 'break the sector’s dependence on fossil fuels', by combining renewable hydrogen with biomethane and captured carbon dioxide