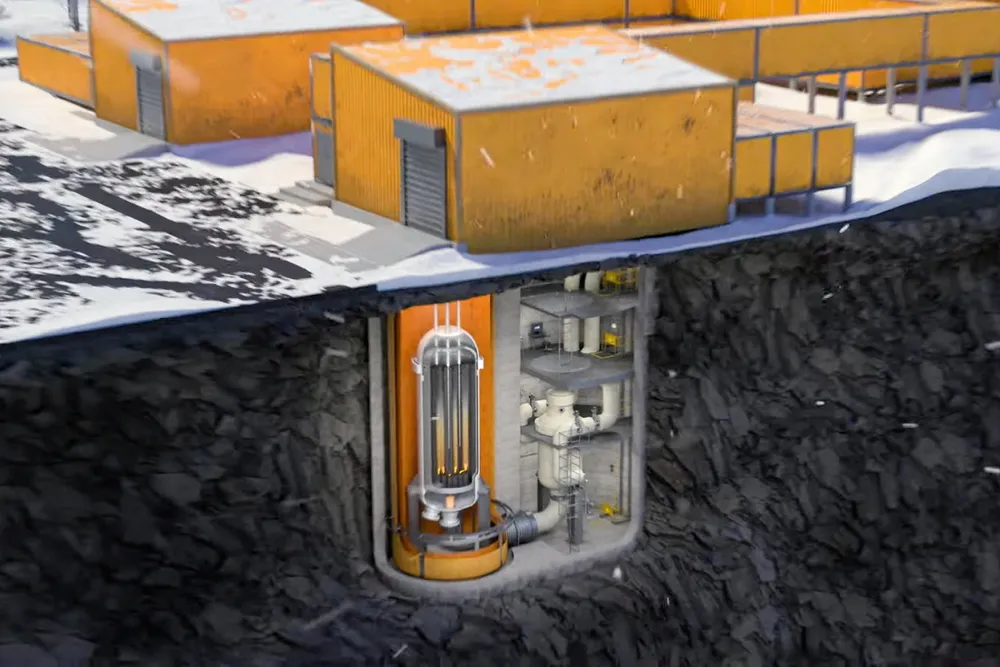

Korean conglomerates plan to produce clean hydrogen from an 'ultra safe' micro nuclear reactor in the heart of Seoul

Hyundai and SK Group sign agreement with US nuclear innovator to build a ‘hydrogen micro hub’ using Bloom Energy’s solid oxide electrolysers