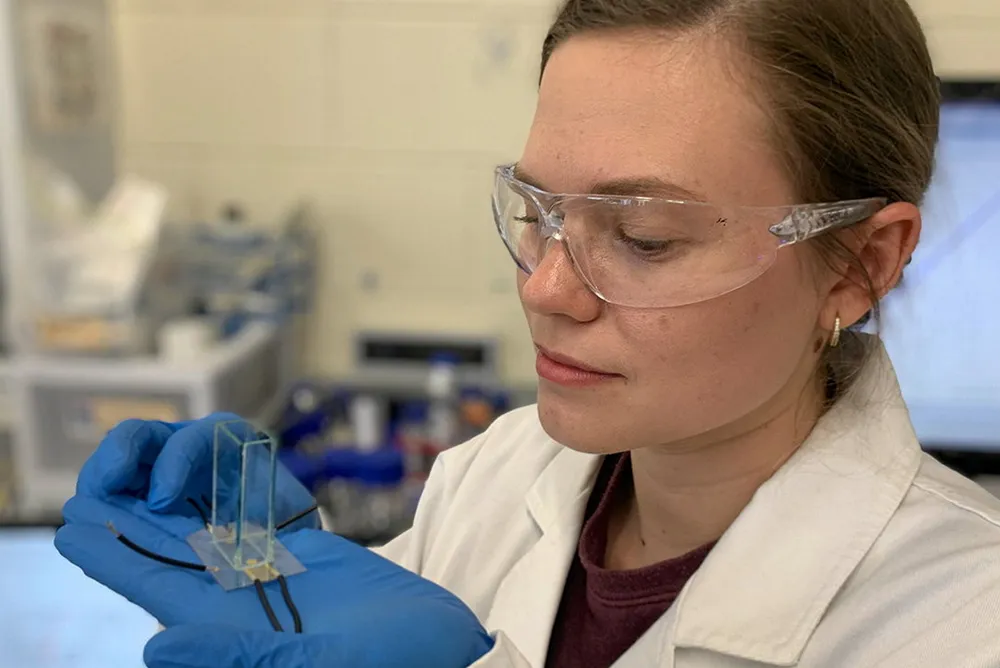

Sound waves boost hydrogen output in electrolyser by a factor of 14, say Australian researchers

But electricity required to produce the high-frequency vibrations means energy-efficiency savings in the lab were only 27% — still a huge improvement on existing tech