'Major milestone for world': Carbon-negative waste-to-hydrogen plant in California gets green light

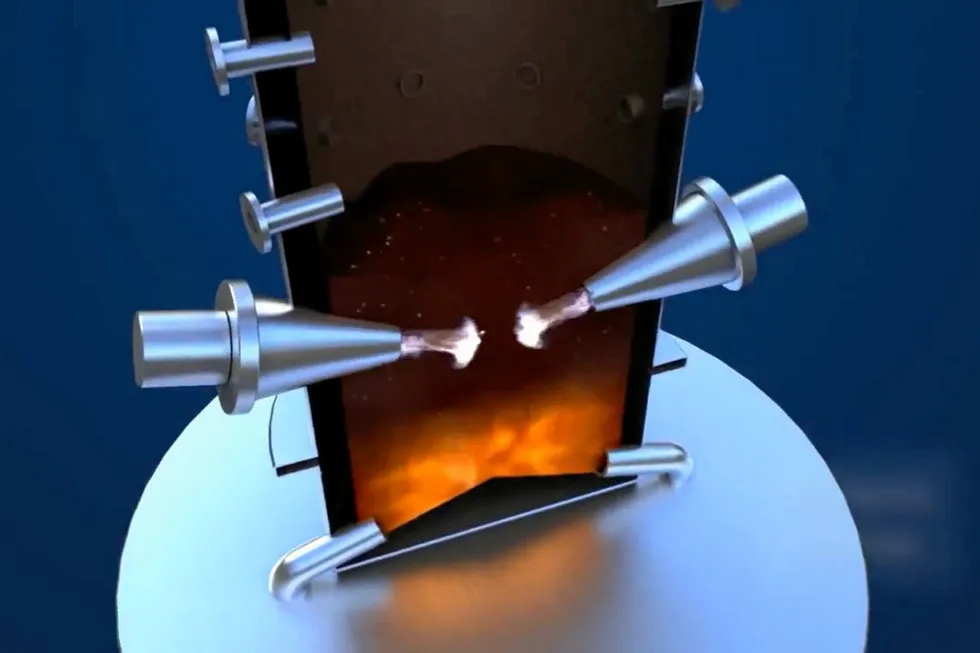

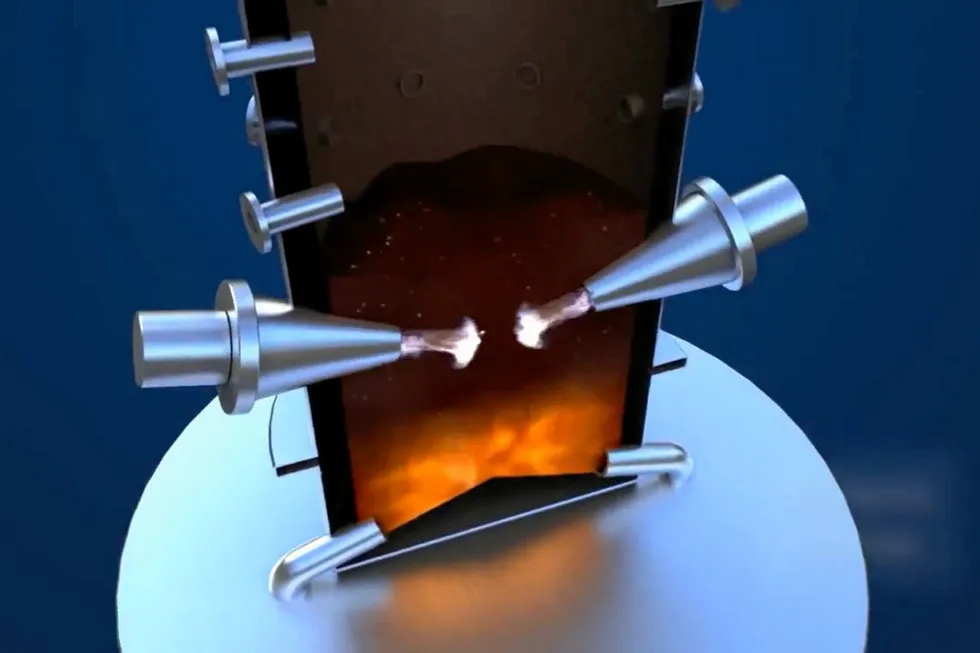

Final investment decision taken by start-up SGH2 Energy on 4,500-tonnes-a year facility after City of Lancaster approves final permits

Final investment decision taken by start-up SGH2 Energy on 4,500-tonnes-a year facility after City of Lancaster approves final permits