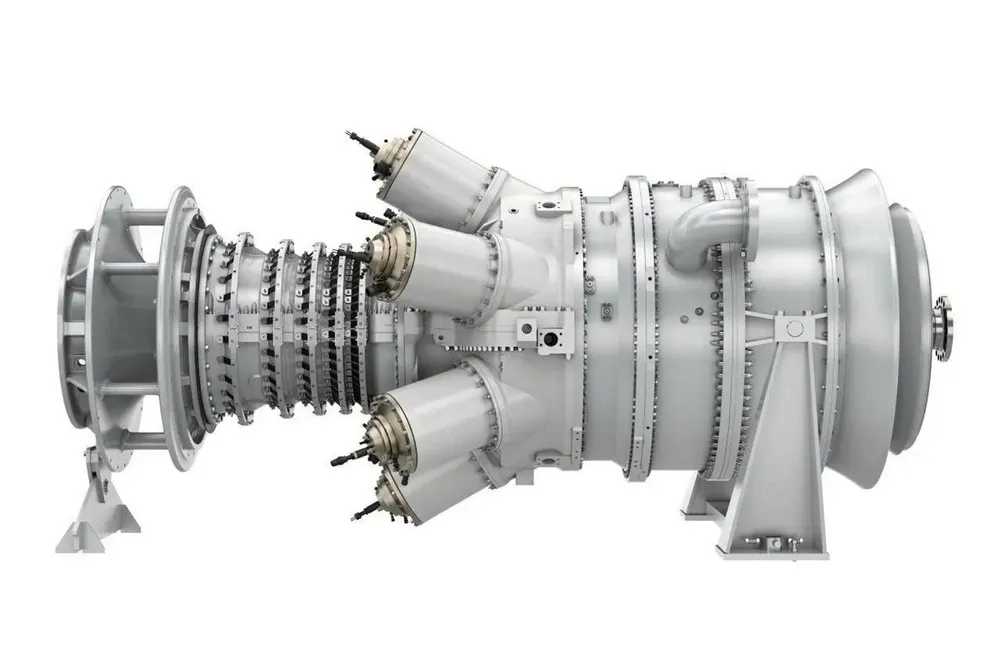

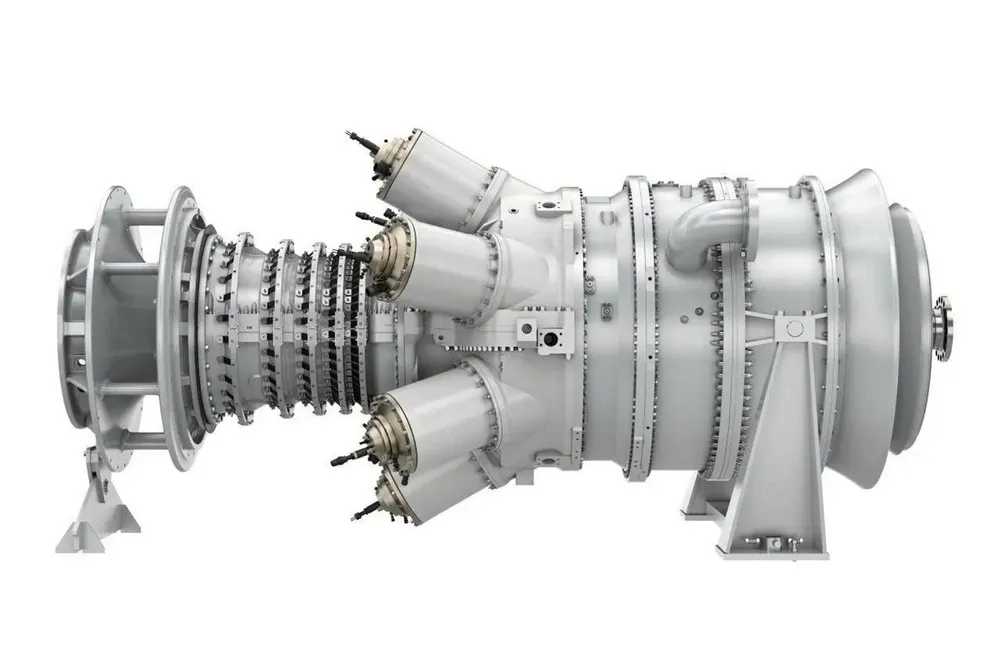

CORRECTION: Siemens Energy burns 100% hydrogen in industrial gas turbine in energy-storage pilot

The Hyflexpower project in western France proves that turbines can be used in power-to-hydrogen-to-power energy storage systems

The Hyflexpower project in western France proves that turbines can be used in power-to-hydrogen-to-power energy storage systems